Projects

Recent Projects

Tiny sub heading that focuses on the topic mentioned above

"Lorem lacus reiciendis illo placerat tempus, temporibus deserunt commodo incidunt error, unde. Facilisis aspernatur. Recusandae illum"

John Doe

CEO At NY Water Park

Commercial Properties

NY Water Park

You can use these sections to highlight the features of heading. Use these paragraphs to focus on the topic you want. Make sure you keep it short and attractive.

- Blandit fugit dicta quibusdam, maxime tempor

- Blandit fugit dicta quibusdam, maxime tempor

- Blandit fugit dicta quibusdam, maxime tempor

Real Estate

Reinstate West Project

You can use these sections to highlight the features of heading. Use these paragraphs to focus on the topic you want. Make sure you keep it short and attractive.

- Blandit fugit dicta quibusdam, maxime tempor

- Blandit fugit dicta quibusdam, maxime tempor

- Blandit fugit dicta quibusdam, maxime tempor

"Lorem lacus reiciendis illo placerat tempus, temporibus deserunt commodo incidunt error, unde. Facilisis aspernatur. Recusandae illum"

Margaret Curtis

Director at West Project

"Lorem lacus reiciendis illo placerat tempus, temporibus deserunt commodo incidunt error, unde. Facilisis aspernatur. Recusandae illum"

Matthew Fox

CEO At Sky Tail Ltd.

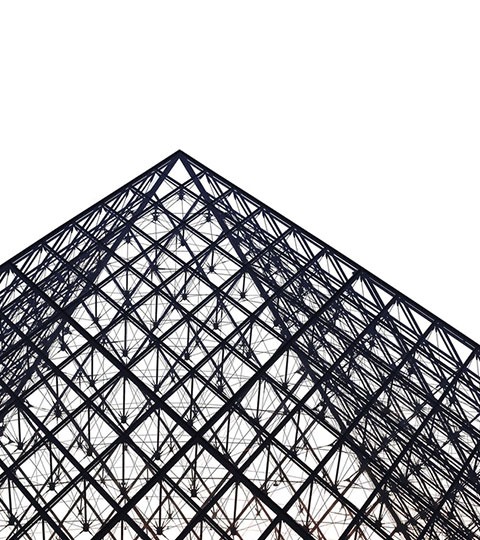

Commercial Properties

Sky Tail Tower

You can use these sections to highlight the features of heading. Use these paragraphs to focus on the topic you want. Make sure you keep it short and attractive.

- Blandit fugit dicta quibusdam, maxime tempor

- Blandit fugit dicta quibusdam, maxime tempor

- Blandit fugit dicta quibusdam, maxime tempor

We Provide the Best Service in Industry

Have a question? Reach us easily by phone, email, or our contact form, let’s talk!